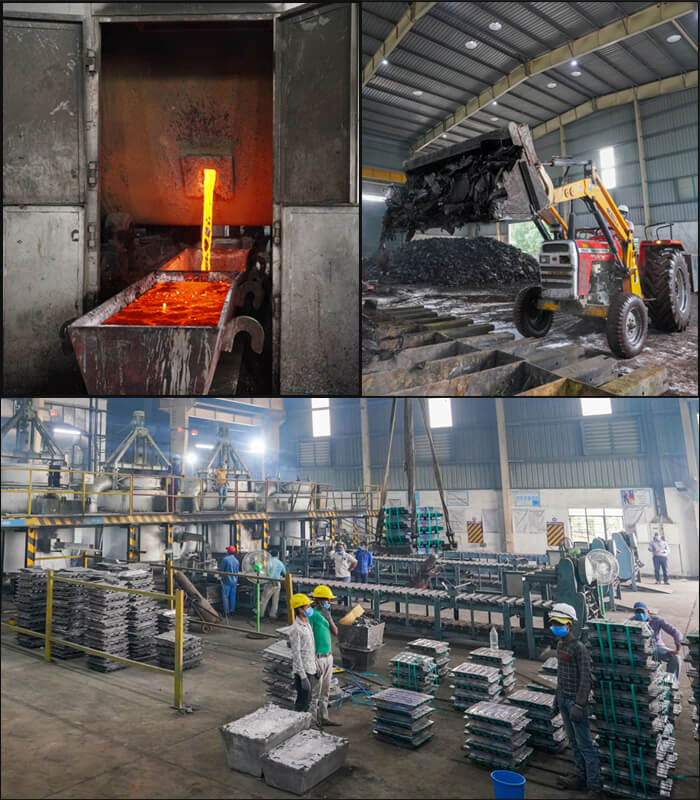

Pilot Industries Limited is a leading producer of Refined Lead & Lead Alloy Ingots in India, which are produced by recycling secondary lead battery scrap (ISRI- RAINS). The company collects local lead battery scrap and imports used battery scrap from various locations around the world. Our lead smelting plant in India is well equipped with advanced technologies and machinery units like Battery Breaking and Separation, Rotary Furnace, Lead Refining and Alloying Pots, Casting, OES spectrometer, etc.

Our state-of-the-art manufacturing substantiates stringent environmental norms in totality. Recycling of secondary lead, old used battery scraps, lead scraps like wheel weights, lead cable sheathings & smelting of lead concentrates, is carried out to produce pure lead and alloys.

Pilot has made a mark by offering worldwide recognized products that meet international standards. Pilot has an installed capacity to produce around 6000 Metric tons of Lead & Lead Alloy Ingots per month. Pilot is committed to providing the Clients with a competitive advantage through a continuous process of quality advancement in all areas of manufacturing. Such commitment is evidenced through a well-formalized Quality Management System accredited with ISO 9001 & ISO 14001.